PRODUCT ID :

FB-VA/FBC-VA

When sachets are pre-produced and stored before being loaded into the next process, additional effort is required to manually align them in the correct orientation and quantity.

The Sachet Sorting Machine automates this task, enabling the re-automation of the packaging line.

With its expandability, it can be integrated into various downstream processes, such as weight checking, cartoning, and outer bag filling— including third-party equipment.

- Coffee

- Tea

Optimal Configurations for Your Needs

Sachet spacing, along with top/bottom and front/back alignment, can be configured according to your needs.

Downstream processes, such as counting and sorting devices, cartoners, and outer bag filling machines, can also be provided to complete your production line.

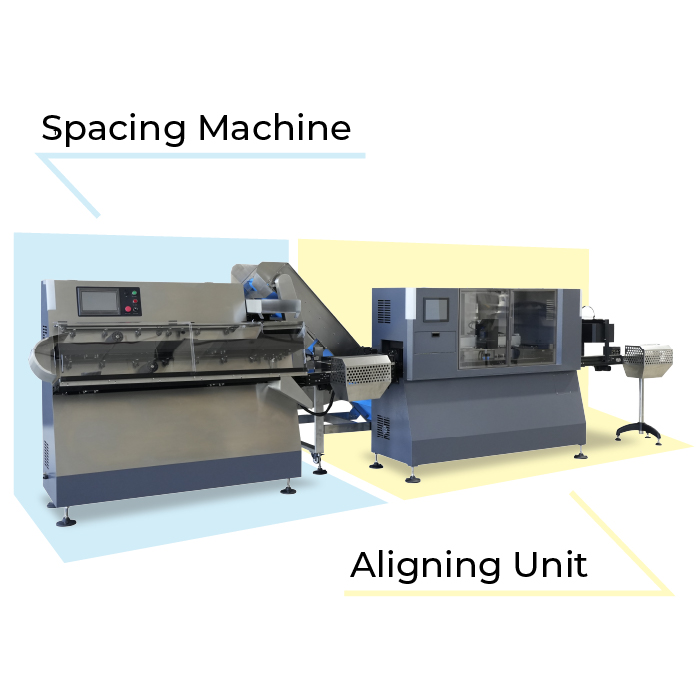

Spacing Machine

This machine separates sachets and guides them to flow in a straight line. It can be used independently or in combination with the aligning unit." When used independently, it is ideal for installation before inspection processes, such as weight checking and counting.

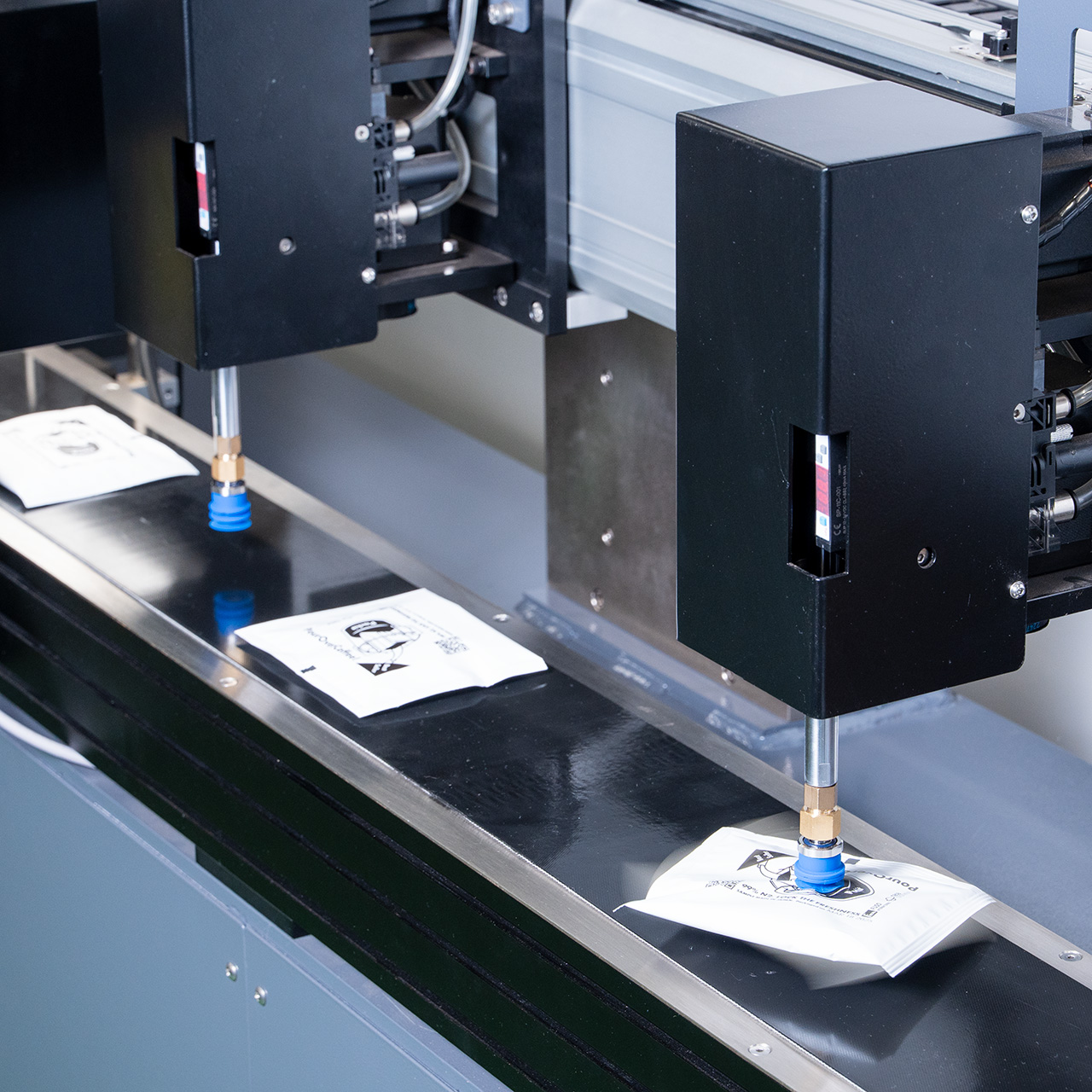

Aligning Unit Using Image Recognition Technology

Through image recognition technology, the spinning and flipping mechanisms of the aligning unit align the products' orientation and front/back faces based on their design.

Recommended Solution: FB-VA/FBC-VA + NRC-50D

When envelope products are pre-produced and stored before being loaded into the cartoner, they must be aligned in a specific orientation and quantity. The Sachet Sorting Machine automates the process, minimizing manual effort and improving overall efficiency.

- Capacity

- Up to 150 bags/minute

- Electrical Power Supply

- 3 Phase 200 V 5.75 kW

- Compressed Air Supply

- 0.6 MPa 600 L/minute

- Supported Envelope Size

- Standard Model:

Length: 60 to 150 mm

Width: 60 to 120 mm

Thickness: 3 to 25 mm

* Other sizes can be discussed upon request.