Nasa Column

25/06/2025

New machines in the lineup!

- Automation

- Machine

- Service

Innovative Proposal: Flexible Merging from Multiple Packaging Machines

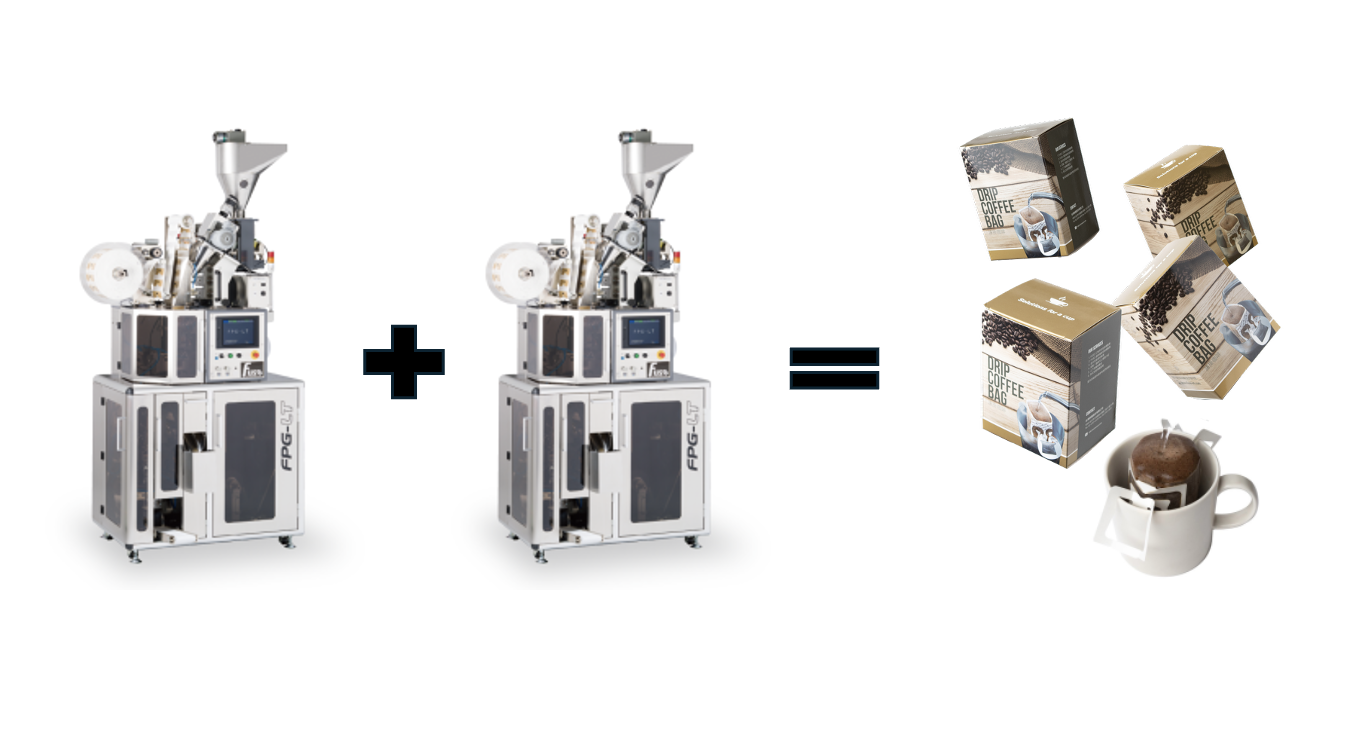

We are thrilled to introduce a groundbreaking solution that achieves product merging from multiple packaging machines with extra simplicity. Let’s envision a scenario where two FUSO drip coffee bag packaging machines (FPG-LT, 60 pieces/min) are linked to produce 20-count boxed products inline. In conventional production processes, it was essential to ensure consistent orientation (front/back and direction) and precise spacing of each drip pack, necessitating strict control right from the packaging machine’s exit to produce boxed products using servo loops and cartoners. This has traditionally necessitated strict control of drip coffee bags right from the packaging machine’s exit. Furthermore, meticulous control design to prevent changes in drip coffee bag’s posture was the standard when passing through inspection equipment such as metal detectors, X-ray checkers, and weight checkers. This has conventionally been a highly complex process, demanding significant effort and numerous adjustments.

Overcoming Traditional Challenges: The Concept of “Flexible Merging”

Unlike the complex controls in conventional production processes, our proposed “Flexible Merging” simply connects the products from two FPG-LT machines via a conveyor. This revolutionary approach eliminates the need for any intricate intermediate controls, enabling easy and trouble-free merging. While the merged products may temporarily experience a disarray in their posture, this is where the essence of our new proposal lies! The disoriented drip coffee bags are reliably processed in a subsequent stage by our two-layer sachet sorting machine, “FBC-VA.”

- Conventional production processes

- New process lines with our FBC-VA

The Stability Brought by the Two-Layer Bulk Sorting Machine “FBC-VA”

The FBC-VA precisely feeds disoriented drip coffee bags into the servo loop while ensuring they are in the

same orientation (relative to the feed direction), on the same side (either front or back), and maintaining consistent spacing. By positioning this process after inspection stages like metal detectors and wegiht checkers, we can now build a highly stable production process without worrying about product posture disruption during the inspection phase. The “envelop arraying” function provided by FBC-VA powerfully supports this new production style of flexible merging from multiple packaging machines.

- Mechanical Structure

Functionality and Future Outlook of FBC-VA

With its unique machine configuration and functional design, the FBC-VA can accommodate a wide variety of envelop arrying needs. By centralizing intricate product posture control in a downstream process, the freedom of operation for upstream packaging machines is enhanced, leading to a dramatic improvement in the overall flexibility and efficiency of the production line. We invite you to anticipate the transformative changes this innovative solution can bring to your production site. If you are interested in more details, please feel free to contact us.