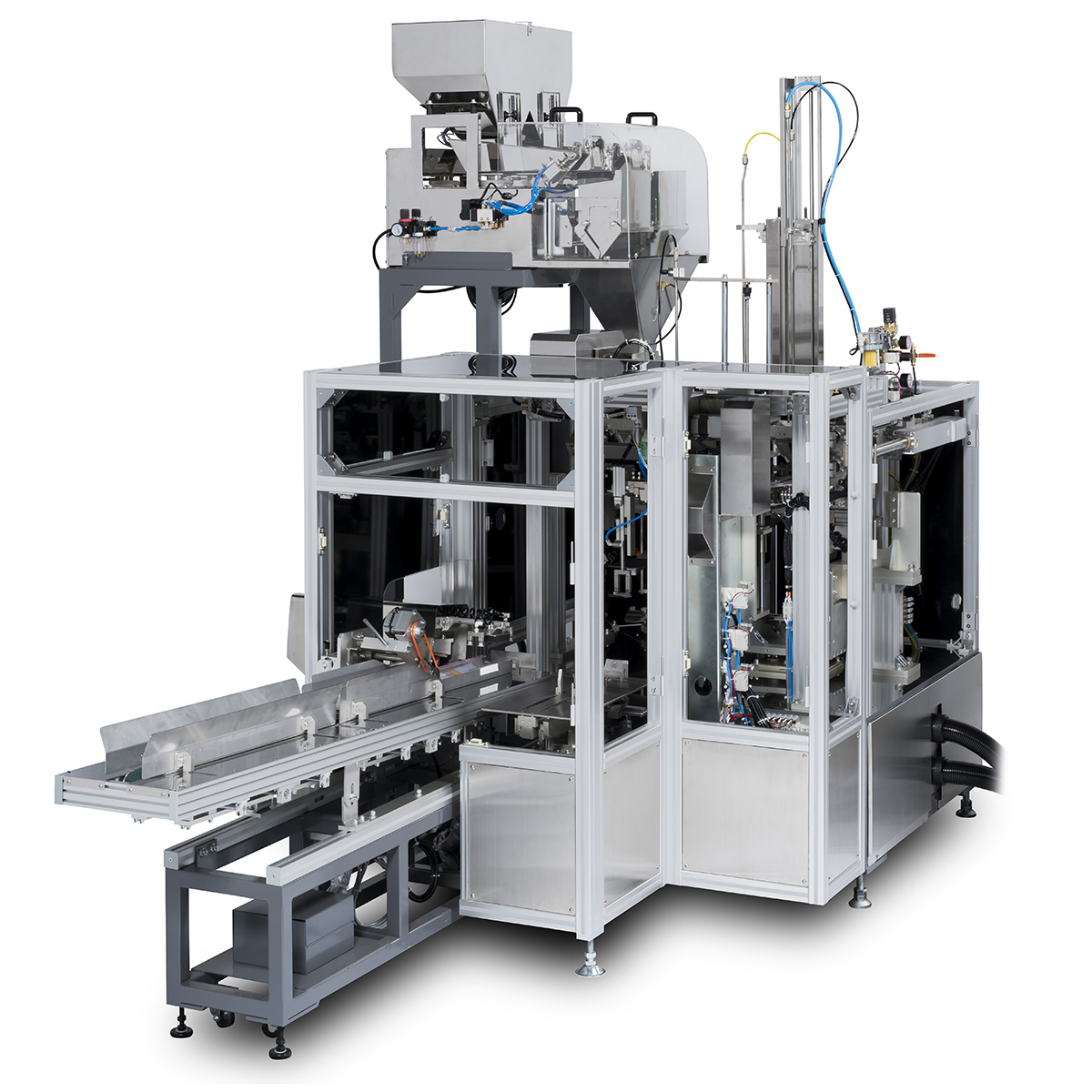

PRODUCT ID :

FR-3

Rotary 4-stage packaging machine designed to pack tea and coffee materials of any particle size into a wide range of pouch sizes. Offering well-balanced productivity and versatility, it supports a variety of premade pouch shapes and features both nitrogen flushing and vacuum packaging functions.

- Coffee

- Tea

Wide Variety of Premade Pouch Shapes Supported

- Various types of premade pouches are supported, including side-gusseted bags with zips and/or a valve (such as flat-bottom pouches with pocket zip), center-sealed bags, 3-side-sealed bags, and doypacks (stand-up pouches).

- Standard support for side-gusseted bags, which are typically difficult to handle, through a specialized bag feeding mechanism.

Standard Support for Large Pouches

Supports a wide range of pouch sizes, from small to large, including pouches that can hold up to 1 kg of coffee materials.

Quick Access to Stored Product Settings

Up to 99 product settings can be stored in memory. Simply select a pre-registered setting to quickly recall the appropriate parameters for your operational needs.

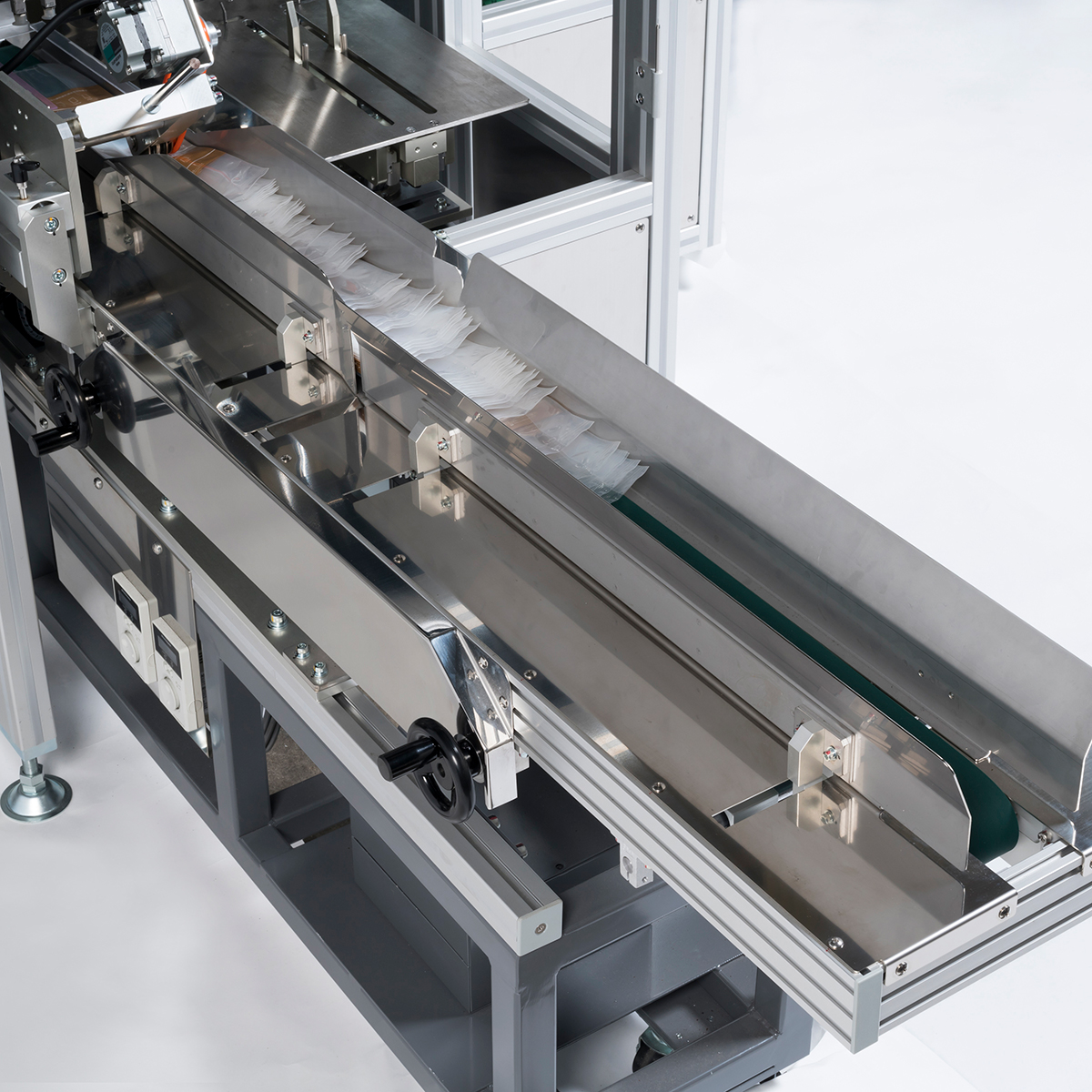

Continuous Production Achieved by Automatic Bag Feeding Conveyor

The automatic bag feeding conveyor reliably supplies pouches, including those with uneven thickness, such as valve-equipped ones, into the machine, ensuring continuous production.

Recommended Solution: FP-MS or FP-100S + FR-3

By integrating the tea bag packaging machine FP-MS or FP-100S with the FR-3, along with a counting system and a feeding lifter, pouch products containing the desired number of tea bags can be packaged.

- Capacity

- Up to 12 bags/minute

- Weight

- 800 kg

- Dimensions

- 1,720 (W) x 1,750 (D) x 2,350 (H) mm

- Electrical Power Supply

- 3 Phase 200 V 3.5 kW

- Compressed Air Supply

- 0.6 MPa 460 L/minute

- Supported Pouch Size

- Length: 150 to 400 mm

Width: 60 to 200 mm